Product & Services

Wireline, Slickline & Braided line Spooling:

A process of removing a cable from a drum/reel and spooling it on to another drum/reel with proper tension control applied so that it is wraps are tight, properly and smoothly spooled ready for jobs. I.e. the cable could be brand new which means it came on the manufacturer's wooden drum/reel, whereby the client would like to remove it from the wooden drum/reel and spool it on to the actual operational steel drum/reel which is mounted on the wireline, slickline or braided line unit. This service can be performed by bringing the unit to our service center while the steel drum/reel is mounted on the unit, or; by simply shipping the steel drum/reels separately without having to bring the unit itself.

Normalizing Electro-Mechanical Cables (EMC)/Wirelines:

Using a Postformer unit in conjunction with the Twister, the cable goes first through the twister so that the cable is twisted (tightened) get it back to its original condition and to make sure there are no loose wires. After that; it goes through the postformer while being gently forced to take a skewed (zigzag) shape creating escape gaps between the armors therefore; relieving all kinks from the wire braid, hence, cable takes back its normal, smooth, round & braided shape.

Cable Brushing, Kink Removal & Lubricating:

While spooling, the cable runs through a specially designed rotating steel wire brushing system, which is adjusted to the cable's size covering 360° of the cable's diameter, thereby, cleaning and removing all kinks, rust and corrosion between the braided wires, in preparation for the cable to go through the lubrication process.

Fluid Cable Cleaner & lubricator:

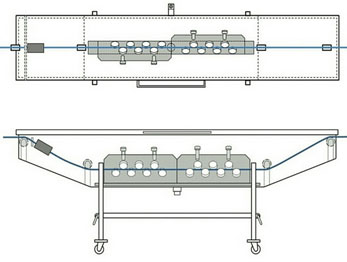

The Fluid Cable Cleaner is basically a basin fitted with a postformer at the base immersed in inhibitor oil. It is designed so that the cable runs through postformer immersed with oil in a skewed (zigzag) shape forcing the cable to slightly open loose so that the oil will penetrate through the armors eventually resting between the outer and inner armor wire layers, forming a seal inhibitor preventing corrosive chemicals and gases from penetrating your wireline

Lubricating and inhibitor injection:

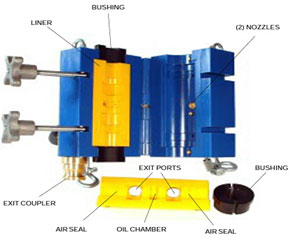

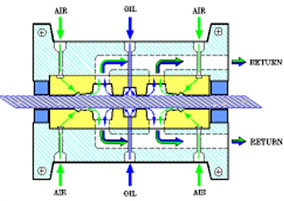

The cable goes through a specially designed housing with a liner and bushings fitted to the cable's diameter size. A compressor then injects a light oil which is a special corrosion inhibitor, it injects the oil to the cable inside the concealed housing, consequently, forcing the inhibitor to penetrate the surface of the outer armor and rest between the outer and inner armor wire layers, forming a seal that prevents corrosive chemicals and gases from penetrating your wireline.

The special light mineral oil used contains corrosion inhibitor package to provide total protection to the wireline cable during adverse operating conditions. This service is designed to protect the wireline cable from the effects of corrosive chemicals commonly found in down- production.

The oil protects the braided wireline cable against the corrosive effects of acids, caustics and most chemicals including H2s, CO2 and salt water, and form a seal around the inner armor to prevent salt water and other chemicals from resting between the armors.

Magnetic Marking:

A process of measuring and placing magnetic marks on the cable at 25 meters intervals with an accuracy of 0.01% or ( .3 meters in 3000 meters) while operated on a cable at a constant tension of 1000 pounds and line speeds between 15 to 185 meters per minute. The operating principal of this process is similar to that of hand marking a cable. The basic differences are that the magnetic marking uses a very sharp magnetic mark in place of a pencil or chalk to mark the intervals. This will provide the best and most accurate length/depth measuring system as a back up to the encoder on the wireline unit spooling system.

Products